Find Good Wiring Duct Manufacturers Here

A Brief Introduction to Wiring Duct

1. Materials

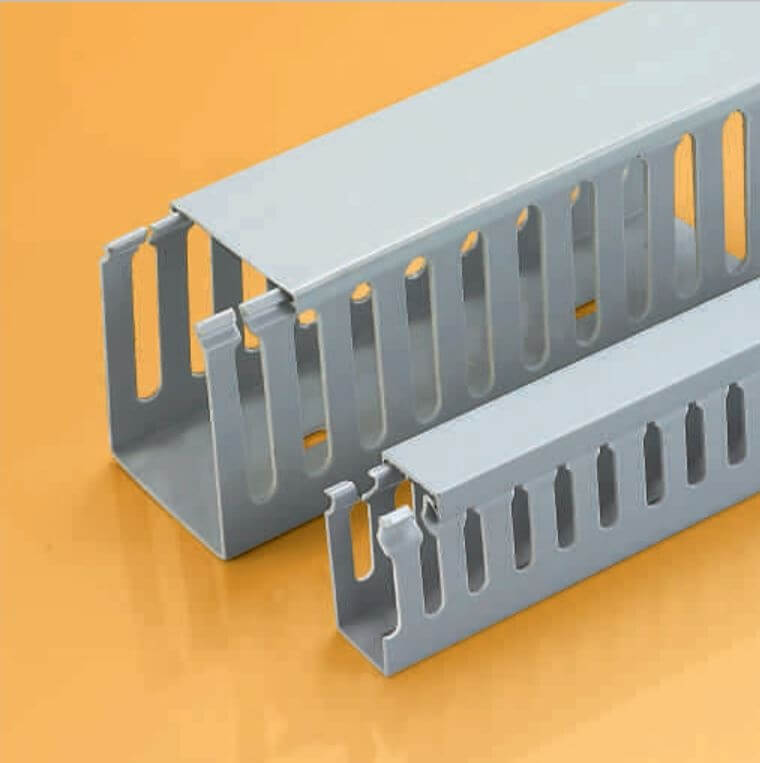

2.Structure:

This product is consisted of the bottom of the tank and the lid. There is the wiring holes along the two sides of the body.

3. Features:

4. Application:

Some Types and Specifications of Wiring Duct

Regarding to the specifications of this kind of product, there are also various.

There are PVC – 20 Series, PVC -25 Series, PVC -25 F Series, PVC -30 Series, PVC- 40 Series, and PVC -40 Q Series.

And there are sizes of 20 mm * 12 mm, 25 mm * 12.5 mm, 25 mm * 25 mm, 30 mm * 15 mm, 40 mm * 20 mm, 14 mm * 24 mm, 18 mm * 38 mm and so on.

The Advantages of Using Wiring Duct?

Wiring duct manufacturers have produced so many products. It is because these products have so many advantages for use.

1. Good Resistance to the Impact

Why will people use this product? It is the wiring duct is resistant to the impact. It can easily protect the wires inside the duct.

Besides, the wires inside the duct will be out the flame and the dangers. This product also does well in the insulation.

2. Good Looking in the Appearance

The general color for the ducts are white. They are the same color with our walls. So there is no influence on the appearance of the wall.

They will cover the lines and wires. So the wires will not be exposed on the wall. Otherwise, it will be very untidy.

3. Long Service Life in the Using

These products can protect our wires and cables for over 50 years. But if there is some outer force to damage the product, its service life will be reduced.

How to install the wiring duct?

Some Tips for the Installation of Wiring Duct

As we all know the installation for the wiring duct is very important. It is playing the role to protect the cables and liens inside.

1. And we also need to note here, the protection of the duct also need the good cables. The cables inside should meet the requirements.

The carrying capacity of the wire should meet the requirements of the line load. And it needs to leave a certain amount of margin.

2. The cables should have sufficient pressure resistance and insulation. And it also requires the cables should have some mechanical strength. Plastic sheathed cables are often used in indoor wiring.

3. And in the process of the installation, you should to avoid the connection joints. It is suggested that you use the whole cable, not the parts in the laying. And the cables need to have complete insulation layer.

It is because the joints of the cables may result in the increase of the contact resistance. And the insulation ability of the joints cables may reduce heavily. These may be some hidden troubles in the cable laying.

4. Most of our indoor cable laying is buried lines laying. If it is the laying of the buried lines, the joint connection parts may have poor connect. And some may result in electric leakage and some electric troubles.

And these are very difficult to check out and repair. So if it is necessary, you can put all the cable joints in the connection boxes and switch boxes. And the head of the lights or the socket boxes are also available.

5. The principle for the laying of the cables is that the laying need to be firm and secure. And the appearance of the duct bought from the wiring duct manufacturers must be also good.

The laying of open-ended wires should be horizontal, vertical and firm. The duct is flat without distortion. And the inner wall is burr-free. The joint is tight and straight. And all kinds of accessories are complete.

Wiring duct will make you be at ease.

Someone says he still has some electric troubles after using wiring duct. I wonder, this product you buy must be from the bad wiring duct manufacturers.

Good quality duct will make the users be at ease. Its teeth have good performance to resist the impact. And when people touch it, you will feel very smooth.

The product can be use as the usual under the bending in ninety degrees. So it is very resistant to the impact. And it has very good flexibility.

When people have the fire accident, don’t be worried about the line systems. They are under the protection of wiring duct.

The duct can add the protection time, compared line system without wiring duct. And it can also stop the spreading of the fire. Besides of the resistant ability to the heat, this product is also cold temperature proof.

In addition, it has the advantages of insulation in the system. And it has supplied perfect arc protection to the lines. So it will be a good helper for the users.

The basic design motivation for the wiring duct manufacture is to offer the safety for the users. This product can hold the big protection for the cables in the mechanical and electrical systems.

Thus, please don’t worry about the safety and security that the cable duct is bringing to us. After the introduction above, you can never hesitate to contact the wiring duct manufacturers.

Go and buy a good wiring duct, it will make you satisfied.

More Information about the Professional Wiring Duct Manufacturer, HONT

We know this product has so many advantages and big functions. Someone are still worried about having bad products. The key point for this is you need to find a superior supplier.

Now let me take you to some good and reliable wiring duct suppliers. HONT is such a professional wiring duct manufacturer in China.

The company is located in the city of Liushi. Liushi is a electrical and electric capital in China. This city offers HONT a convenient transportation.

The company is near to the air port. And it is also near to the Ningbo port and Shanghai port. This good location gives fast delivery to the carrying goods to the port for the shipping.

It is one of the biggest factories manufacturing and selling Wire Duct. The company has been insisting the principle of “High quality, high service, best price” since 1997 we are founded.

During the ten years’ experience, the company has attracted customers from overseas, Africa, India, Australia, Russia, Europe, Middle East and etc. Its market has been expanded to Europe, America, Asia and so on.

The strict quality monitoring system and the experienced technology power have gained more and more customers for HONT.

The company has been equipped with advanced machines. And it has excellent teams in innovation and researching. HONT is supplying slotted wiring ducts, cable ties and various low voltage electrical products for customers and clients.